Michigan Is An Excellent Bevel Gear Manufacturer And Service Provider.

Since 2010, in addition to operating a bevel gear factory, Shanghai Michigan has also established long-term partnerships with 5 well-known factories in the gear industry in China. As a representative of the Overseas Business Department, we focus on developing overseas business, and cooperate with 12 other high-quality gear suppliers to provide gears of different types, sizes and uses, including some top gear companies in China and participants of the AGMA gear standard. With a strong supply chain, we can greatly meet the needs of overseas customers in terms of product quality, control and delivery.

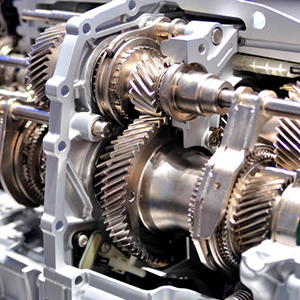

As a representative of China's international trade, we provide spur gears, helical gears, internal gears, bevel gears, hypoid gears, crown gears and pinions, worm gears, planetary gear, gear rack and pinion and gearboxes, etc.

With 13 years of experience in gear processing, We fully controls key factors such as concept, design, prototype, verification, mass production, and final application. Through rich knowledge reserves and strong equipment capabilities, Michigan conducts integrated product development and allows customers to participate in it.

Michigan is not only an excellent bevel gear manufacturer and service provider, but also willing to work hard to ensure the reliability and stability of your gear transmission system. To ensure this, we have cooperation and academic exchanges with relevant industries, and for some components we can process and manufacture in-house. When needed, we can match you with the most suitable components in the most economical way, and carry out installation and testing.

We Are Proud To Have Received These Patents And Certificates.

We are committed to consistently staying ahead of the industry by embracing innovation, investing in cutting-edge technology, and continuously improving our processes and capabilities to maintain industry leadership and provide our customers with the best possible solutions.

Certificates And Honors

───── 31 Patents in total & 9 Invention Patents ─────