Strict Requirements For Raw Materials

WE ATTACH IMPORTANCE TO THE INFLUENCE OF STEEL ON THE QUALITY OF GEARS.

At Shanghai Michigan, high-quality raw materials are the key to producing durable, precise and efficient gears. We understand the importance of steel in gear manufacturing and work closely with our customers to determine the best steel grade for their specific needs. Whether it's carbon steel or alloy steel, our team of experts are well versed in selecting the right material for the job.

Our large warehouse with approximately 500 tons of raw material allows us to start gear production almost immediately. This means we can quickly turn around projects and start in-house forging or heat treating processes while our competitors are still looking for material suppliers. However, we recognize that not all mills are created equal and that the quality of their steel can vary widely. That's why we only work with reputed steel mills such as ArcelorMittal, Nisshin Steel, OVAKO, Sumitomo, CITIC (Xingcheng Steel) and Baosteel to ensure we use high quality, consistent and reliable raw materials to build our Quality product gear.

Advanced Forging Knowledge Leads To Higher-Quality Gears.

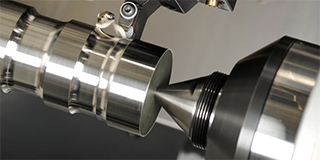

We understand the importance of high performance and durable gears, which is why forged gear blanks play an important role in the gear production process. Through forging, gear blanks gain strength and density, which increases life and performance. By improving the material's microstructure and grain flow, its mechanical properties are also enhanced.

In Shanghai Michigan, as a custom gear manufacturer, we prioritize quality control and cost-effective gear blank forging. Our advanced forging equipment and skilled employees enable us to forge high-precision gear blanks, even those with complex shapes and tight tolerances.

Our commitment to producing gears to the highest quality standards is reflected in our continuous improvement of forging knowledge to minimize material waste during gear cutting. With us, you can expect reliable products tailored to your specific needs.

Forging Capacity

Besides Spur Gears,Bevel Gears, Casting and Forging are also an important business for us.

Production Range

|

Free forging |

Tons |

Max. diameter |

|

500tons |

800mm |

|

|

Die forging |

Press Machine |

Max. diameter |

|

1600T |

450mm |

|

|

Cold heading |

Heading Ratio |

Max. diameter |

|

1.414 |

48mm |