HELICAL GEARS feature angled teeth, setting them apart from other gear types. This design delivers smoother engagement, reduced noise, and exceptional durability. Industries rely on them for high-speed, high-load applications.

●Helical gears account for 20% of the global industrial gear market.

| Gear Type | Tooth Design Description |

|---|---|

| Spur Gear | Teeth are straight and parallel to the axis of the gear. |

| Helical Gear | Teeth are cut in a helical shape, inclined at a helix angle with the gear axis, allowing for gradual engagement. |

| Bevel Gear | Teeth can be straight or spiral, oriented along the gear axis, affecting engagement characteristics. |

Key Takeaways

●Helical gears have angled teeth that provide smoother engagement, reducing noise and increasing durability.

●These gears excel in high-speed and high-load applications, making them ideal for industries like automotive and machinery.

●Regular maintenance and proper lubrication are essential for maximizing the efficiency and lifespan of helical gears.

Helical Gears Mechanics

Helical Gears Structure

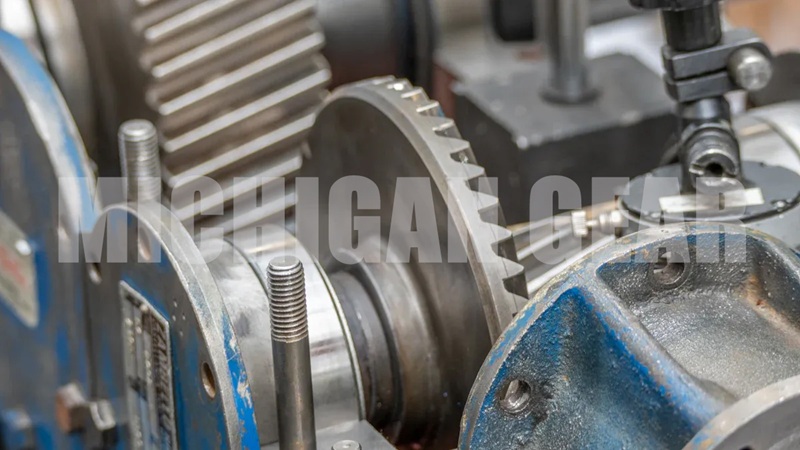

HELICAL GEARS stand out because of their unique tooth design. The teeth are cut at an angle to the gear axis, forming a spiral or helix shape. This angled arrangement allows the teeth to engage gradually, unlike the straight teeth of spur gears. Manufacturers can produce right-handed or left-handed configurations, depending on the direction of the helix. Most industrial applications use helix angles between 15° and 30°, which directly affect gear performance.

| Application Type | Base Helix Angle | For Quiet Operation | When to Use |

|---|---|---|---|

| General industrial | 15–20° | 20–25° | Standard power transmission |

| Precision positioning | 20–25° | 25–30° | Accuracy-critical systems |

| High-speed (>1000 RPM) | 25–30° | 30–35° | Minimize dynamic loads |

A higher helix angle increases the contact area and smoothness but also raises axial loads, which may require stronger bearings. Precision in manufacturing is crucial. Accurate tooth profiles, pitch, and helix angles ensure smooth operation and long-lasting performance.

Note: Advanced manufacturing methods, such as cold extrusion, reduce energy use and waste, making the production of HELICAL GEARS more sustainable.

Power Transmission Science

The science behind HELICAL GEARS centers on how their angled teeth mesh. The gradual engagement process creates a larger contact area between the teeth. This design distributes the load more evenly and reduces stress on each tooth. As one pair of teeth begins to engage, another pair is already in contact, resulting in a higher contact ratio. This overlapping action leads to quieter and smoother operation compared to spur gears, which mesh all at once.

HELICAL GEARS excel in power transmission. Their efficiency ranges from 94% to 98%, making them ideal for high-speed and high-load machinery. The gradual meshing increases contact time, which boosts efficiency and reduces energy loss. These gears can also transfer power between non-parallel shafts, offering flexibility in design.

Proper lubrication plays a vital role in maintaining efficiency and extending gear life. Lubricants reduce friction, protect against wear, help dissipate heat, and prevent corrosion. Regular maintenance and high-quality lubricants keep gears running smoothly and efficiently.

Advantages of Helical Gears

HELICAL GEARS offer several key advantages that make them the preferred choice in many industries:

●Durability and Longevity: In automotive transmissions, HELICAL GEARS last between 10,000 and 20,000 hours, which is up to 70% longer than spur gears.

●Noise Reduction: The gradual engagement and higher contact ratio result in quieter operation.

| Gear Type | Noise Level (dBA) |

|---|---|

| High Contact Ratio Helical | 80-85 (quietest, premium) |

| Standard Helical | 85-95 (good reduction) |

| High Contact Ratio Spur | 85-95 (moderate improvement) |

| Standard Spur | 85-95 (higher impact) |

| Non-involute Spur | >95 (noisiest) |

●Shock Loading Reduction: Several factors contribute to reduced shock loading:

●Design of the gear reducer

●Application factors (input/output torque)

●Dynamic factors (mesh stiffness, imbalance)

●Load distribution across gear width

●Service design loads

●Smooth operation and gradual engagement

●Efficiency and Energy Savings: HELICAL GEARS operate with high transmission efficiency, reducing energy consumption and heat generation. Gearboxes using these gears can achieve efficiency rates over 95%, saving energy in industrial processes.

●Performance Under Extreme Conditions: These gears withstand high speeds and heavy loads, maintaining efficiency even under intense pressure and temperature.

Tip: Regular inspection and proper alignment further enhance gear performance and prevent common issues like wear, fatigue, and misalignment.

HELICAL GEARS combine advanced design, high efficiency, and durability. Their structure and operation deliver superior results in demanding environments, making them the smart choice for modern machinery.

Helical Gears Applications

Automotive and Machinery

HELICAL GEARS power some of the most demanding machines in the world. Many industries rely on them for their unique benefits:

●Automotive

●Industrial machinery

●Material handling systems

●Fertilizer, printing, and earth-moving equipment

●Steel, rolling mills, and textile production

These industries choose helical gears for reliable torque transmission and efficiency at high speeds. The angled teeth allow for smooth operation and higher load capacity. Machines run quieter and last longer because of reduced vibration and wear. This means less downtime and more productivity.

Tip: If you want your equipment to handle steady loads and operate with less noise, helical gears are the smart choice.

Power Generation and Pumps

Power plants and industrial pumps demand gears that can handle extreme conditions. Helical gears deliver outstanding performance in these settings.

| Advantage | Description |

|---|---|

| Smooth Operation with Reduced Noise | Gradual tooth engagement means quieter, low-vibration operation. |

| High Power Transmission Efficiency | Efficiently transmits power (94%-98%) between non-parallel shafts, perfect for high-speed use. |

| High Durability and Life | Increased contact area reduces wear, extending gear lifespan. |

Pumps using helical gears often reach efficiency levels above 90%. Their design handles high pressures and heavy-duty cycles, making them ideal for energy-intensive industries.

Everyday Uses

HELICAL GEARS also improve the appliances you use every day:

●Washing machines

●Mixers

These gears provide smoother and quieter operation than other gear types. The gradual engagement of teeth reduces impact forces and vibrations. This leads to longer-lasting, more reliable household devices. Helical gears handle twisting and spinning forces with ease, ensuring your appliances work efficiently for years.

Imagine sliding two boards past each other—this is how HELICAL GEARS work, creating smooth and quiet motion.

●They deliver efficient power transmission.

●They reduce noise and vibration.

●Their strong design supports heavy loads in cars, machines, and even aerospace.

Appreciate the engineering that powers your world every day!

FAQ

What makes helical gears better than spur gears?

Helical gears run quieter and last longer. Their angled teeth provide smoother power transfer. Choose helical gears for high performance and less maintenance.

Can helical gears handle heavy loads?

Absolutely! Helical gears excel under heavy loads. Their design spreads force across multiple teeth. This means more strength and reliability for your equipment.

Where should I use helical gears?

Use helical gears in cars, industrial machines, and pumps. They deliver efficient, quiet, and durable performance. Upgrade your systems for better results!

Post time: Feb-06-2026