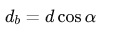

Splines are essential mechanical components used to transmit torque between shafts and mating parts like gears or pulleys. While they may seem simple, selecting the correct spline type and standard is critical for ensuring performance, compatibility, and manufacturing efficiency.

1. ISO Standards (International)

ISO 4156 – Defines straight and helical involute splines with 30°, 37.5°, and 45° pressure angles.

ISO 4156-1: Dimensions

ISO 4156-2: Inspection

ISO 4156-3: Tolerances

ISO 14 – Covers metric module splines (older standard, largely replaced by ISO 4156).

2. ANSI Standards (USA)

ANSI B92.1 – Covers 30°, 37.5°, and 45° pressure angle involute splines (inch-based).

ANSI B92.2M – Metric version of involute spline standard (equivalent to ISO 4156).

3. DIN Standards (Germany)

DIN 5480 – German standard for metric involute splines based on the module system (widely used in Europe).

DIN 5482 – Older standard for fine-module involute splines.

4. JIS Standards (Japan)

JIS B 1603 – Japanese standard for involute splines (equivalent to ISO 4156 and ANSI B92.2M).

5. SAE Standards (Automotive)

SAE J498 – Covers involute splines for automotive applications (aligned with ANSI B92.1).

Key Parameters of Involute Splines:

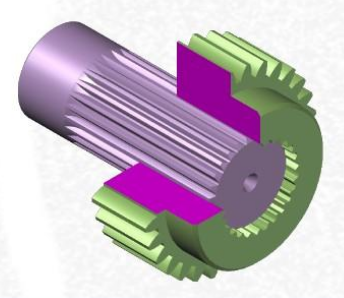

1. Number of Teeth (Z)

● The total number of teeth on the spline.

● Affects torque transmission and compatibility with mating parts

2. Pitch Diameter (d)

● The diameter at which the tooth thickness equals the space width.

● Often used as a reference diameter for calculations.

● Critical for determining the fit and torque capacity.

3. Pressure Angle (α)

● Common values: 30°, 37.5°, and 45 °

● Defines the shape of the tooth profile.

● Impacts contact ratio, strength, and backlash.

4. Module (Metric) or Diametral Pitch (Inch): Defines tooth size.

5. Major Diameter (D)

● The largest diameter of the spline (tip of external teeth or root of internal teeth).

6. Minor Diameter (d₁)

● The smallest diameter of the spline (root of external teeth or tip of internal teeth).

7. Base Diameter (d_b)

● Calculated as:

● Used for involute profile generation.

8. Tooth Thickness and Space Width

● Tooth thickness (on the pitch circle) must match space width on mating part.

● Affects backlash and fit class (clearance, transition, or interference).

9. Form Clearance (C_f)

● Space at the root to allow tool clearance and prevent interference.

● Especially important in internal splines.

10. Fit Class / Tolerances

● Defines the clearance or interference between mating parts.

● ANSI B92.1 includes fit classes like Class 5, 6, 7 (increasing tightness).

● DIN and ISO use defined tolerance zones (e.g., H/h, Js, etc.).

11. Face Width (F)

● Axial length of the spline engagement.

● Affects torque transmission and wear resistance.

Fit Types:

Side Fit – Transmits torque via spline flanks.

Major Diameter Fit – Centers on the major diameter.

Minor Diameter Fit – Centers on the minor diameter.

Tolerance Classes: Defines manufacturing precision (e.g., Class 4, Class 5 in ANSI B92.1).

Applications:

Automotive transmissions

Aerospace components

Industrial machinery shafts

Post time: Jul-23-2025