When you pick spur gears, you get great power transfer. The efficiency can be 98% or even more. Spur gears have a simple design. This makes them easy to set up. It also helps save money. Here is how spur gears compare:

| Gear Type | Efficiency |

|---|---|

| Spur | 98% or higher |

| Helical | Slightly lower |

| Bevel | Lower than spur |

| Worm | Noted for lower efficiency |

These good things help your machines work well. They also make machines reliable in many industries.

Key Takeaways

●Spur gears work very well. They can be up to 99% efficient. This means they do not waste much energy when moving power. Their simple design makes them easy to put in and take care of. This helps save time and money. Spur gears can be used in many different jobs. Many industries use them, so they are a good choice for lots of things.

Efficiency and Simplicity

High Power Transmission

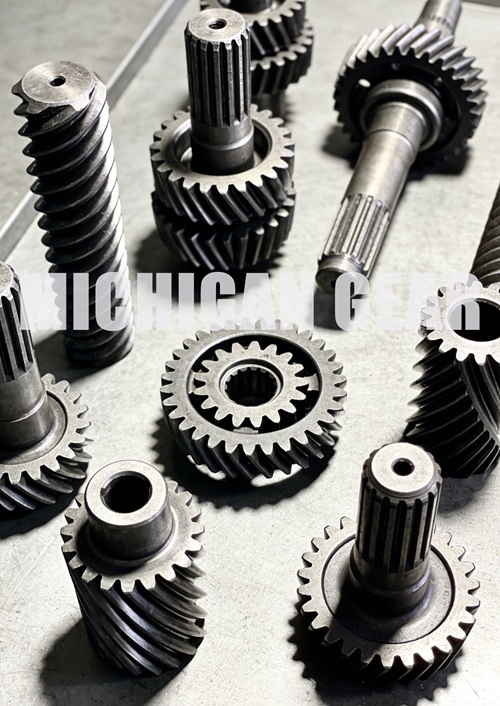

When you want to move power from one place to another, spur gears really shine. Their straight teeth mesh directly, which means less friction and more energy goes where you need it. You can count on spur gears to deliver power with very little loss—sometimes as high as 99% efficiency. That means almost all the energy you put in comes out as useful work.

●Spur gears often reach 98–99% efficiency.

●Helical gears lose a bit more energy because their teeth slide against each other.

●With spur gears, you get reliable power transfer between parallel shafts.

This high efficiency is a big reason why you see spur gears in machines that need to save energy, like automotive transmissions. You get smooth motion, steady speed, and less wasted power.

Simple Design and Installation

Spur gears keep things simple. Their teeth sit straight and perpendicular to the gear’s axis. This design makes them easy to line up and install. You do not need special tools or complicated steps. You just mount the gears on parallel shafts, and they are ready to go.

Tip: The simple shape of spur gears means you can quickly figure out gear ratios and plan your setup without a headache.

Here are some reasons why installation feels easy:

●Straightforward design and manufacturing

●Predictable engagement for easy calculations

●Fewer parts to worry about

Because spur gears are so simple, you spend less time on setup and more time running your machines. Maintenance also becomes easier. You do not have to deal with tight tolerances or tricky alignments. This means you can keep your equipment running smoothly with less effort.

Cost Benefits

You want to save money, and spur gears help you do just that. Their simple design means they cost less to make. Manufacturers can use standard processes like hobbing or shaping, which are fast and efficient. This keeps prices down, especially when you need a lot of gears for a big project.

●Spur gears usually cost 20–35% less than helical gears.

●Helical gears need extra finishing and special bearings, which adds to the price.

Spur gears also help you save on maintenance. Their straightforward specs mean fewer surprises and lower costs over time. You do not have to budget for expensive repairs or complex replacements. This makes spur gears a smart choice when you want reliable performance without breaking the bank.

Note: Choosing spur gears can make your whole project more predictable, from quoting to final installation.

In the end, spur gears give you a winning mix of high efficiency, easy installation, and real savings. You get reliable power, simple setup, and more value for your money.

Spur Gears vs. Other Gears

Noise and Vibration

Spur gears are usually louder than other gears. Their teeth hit each other all at once. This makes a lot of noise and shaking. Helical gears are different. Their teeth slide together slowly. This makes them much quieter. You can see the difference in this table:

| Gear Type | Engagement Style | Impact Level | Typical Noise |

|---|---|---|---|

| Spur Gear | Instantaneous, full-width | High | Loud |

| Helical Gear | Gradual, angled | Low | Quiet |

Spur gears shake more because of how their teeth meet. Every time the teeth touch, there is a shock. Helical gears do not shake as much. They work better when spinning fast.

Versatility in Applications

Spur gears are used in many machines. You can find them in robotics and automation. They are also in cars and airplanes. Food factories and hospitals use them too. Big machines use spur gears for power and speed. Here is a table that shows where spur gears are used:

| Machinery Type | Application Description |

|---|---|

| Robotics | Precise control in movements |

| Industrial Automation | Efficient power transmission |

| Automotive | Speed regulation in transmissions |

| Aerospace | Reliable performance in aircraft systems |

| Food Processing | Processing and packaging food products |

| Medical Devices | Precise motion control |

| Heavy Machinery | Power conversion and speed control |

Spur gears are flexible. You can use them in simple or complex machines.

Speed and Torque Adjustments

Spur gears help you control speed and torque well. They work best at low or medium speeds. They are good for light or medium loads. You can see them in washing machines and road rollers. Conveyor systems use them too. If you need to change speed or make more torque, spur gears help. They let you move things exactly where you want.

Tip: Spur gears are great for easy speed changes or strong torque.

If you need smooth running at very high speeds, use other gears. For most jobs, spur gears give you good control and work well.

You get top efficiency with spur gears. Their simple design saves you time and money. Spur gears work in many industries and handle tough jobs.

●High mechanical efficiency (up to 98%)

●Fast manufacturing and easy setup

●Reliable performance and long life

Try spur gears for your next project!

FAQ

What makes spur gears so efficient?

You get high efficiency because spur gears have straight teeth. These teeth mesh directly, so you lose very little energy during power transfer.

Can you use spur gears for high-speed machines?

You can use spur gears for moderate speeds. If you need very high speeds, you might want to look at other gear types.

How do you choose the right spur gear size?

You pick the size based on your machine’s speed and torque needs. Check the gear ratio and shaft size before you buy.

Post time: Feb-03-2026