Spur Gear Fundamentals and How They Work

Key Takeaways

●Spur gears are essential for reliable power transmission in machines, featuring straight teeth that connect parallel shafts efficiently.

●Choose spur gears for their simplicity and cost-effectiveness, making them ideal for various applications like automotive, industrial machinery, and household appliances.

●Consider material selection carefully; metal gears handle heavy loads while plastic gears offer quiet operation, ensuring you match the gear type to your specific needs.

What Is a Spur Gear

| Feature | Spur Gear | Helical Gear |

|---|---|---|

| Tooth Orientation | Straight, parallel to axis | Angled to axis |

| Noise Level | Higher | Lower |

| Axial Thrust | None | Yes |

| Cost | Lower | Higher |

How Spur Gears Work

You rely on spur gears to transmit motion and power by meshing their teeth together. When one gear (the driving gear) rotates, its teeth push against the teeth of the other gear (the driven gear). This action causes the driven gear to rotate in the opposite direction. The speed and torque of the driven gear depend on the gear ratio, which you calculate by comparing the number of teeth on each gear.

You can only use spur gears to connect parallel shafts. The teeth engage all at once, which creates a clicking sound and higher noise levels compared to other gears. The design of a spur gear involves several important factors, such as pitch diameter, module, pressure angle, addendum, dedendum, and backlash. These factors help you determine the gear’s ability to handle different loads and speeds.

You also see spur gears used with racks to convert rotary motion into linear motion. When the spur gear turns, it moves the rack in a straight line. This setup appears in machines like industrial robots and automated production lines, where you need precise movement.

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

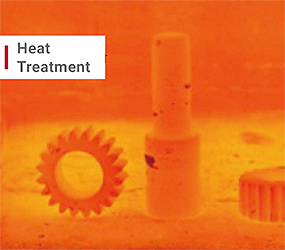

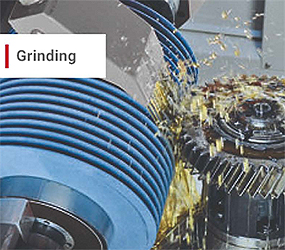

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package