Custom Planetary Gear Set for Planetary Reducer

Advantages

1. Compact & High-Torque Design

2. Superior Durability & Corrosion Resistance

3. Precision Engineering & Customization

Technical Specifications

| Component | Material & Design | Key Features |

|---|---|---|

| Sun Gear | Corrosion-resistant alloy steel (17CrNiMo6/42CrMo) | Connected to carrier, high torque capacity |

| Planet Gears | Precision-machined alloy steel | Independent rotation + orbital movement around sun gear, load sharing |

| Ring Gear | Heat-treated alloy steel | Fixed to output shaft (e.g., propeller shaft), stable power output |

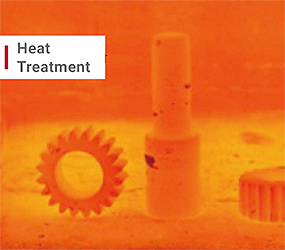

| Surface Treatment | Carburizing, nitriding | Wear-resistant, corrosion-proof |

| Core Performance | Low backlash, high efficiency, high reliability | Suitable for continuous load & vibration |

| Customization | OEM/reverse engineering available | Tailored gear ratios, sizes, and applications |

Applications

Our planetary gear set for planetary reducer is widely used in:

● Marine applications: Ship propulsion systems, winches, cranes, deck machinery, offshore vessels, cargo ships, port equipment.

● Industrial applications: Industrial reducers, robotics gearboxes, automation equipment, mining machinery, and more.

Manufacturing & Quality Assurance

At Michigan Gear, we adhere to strict production standards from raw material selection to final delivery:

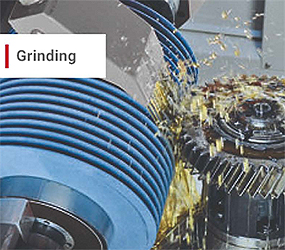

● In-House Production: All processes (forging, heat treatment, machining, grinding, inspection) are completed in our state-of-the-art facility—staffed by 1,200 professionals and ranked among China’s top 10 gear manufacturing enterprises.

● Advanced Equipment: Equipped with precision CNC lathes, vertical/horizontal CNC hobbing machines, gear testing centers, and imported inspection tools (Brown & Sharpe three-coordinate measuring machine, German Marl cylindricity instrument, Japan roughness tester).

● Quality Control: Key processes (marked "Δ") and special processes (marked "★") undergo strict inspection. We provide comprehensive reports (dimension report, material report, heat treat report, accuracy report) before shipping for customer approval.

● Patented Technology: Holder of 31 invention patents and 9 utility model patents, ensuring innovative and reliable product design.

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package