Cycloidal Reducer:Precision Drive for Diverse Industries

Featureds

1.Compact Design: Its space-efficient architecture makes it ideal for applications where installation space is limited. Whether integrated into robotic arms requiring tight configurations or compact automated machinery, the cycloidal reducer maximizes power density without sacrificing performance.

2.High Gear Ratio: Capable of achieving substantial speed reduction ratios, typically ranging from 11:1 to 87:1 in a single stage, it enables smooth, low-speed operation while delivering high torque output. This makes it perfect for applications that demand precise control and powerful driving force.

3.Exceptional Load Capacity: Built with robust materials and advanced engineering, cycloidal reducers can handle heavy-duty loads, ensuring stable operation even under extreme working conditions. Their ability to withstand shock loads and vibrations further enhances their reliability in industrial environments.

4.Superior Precision: With minimal backlash and high transmission accuracy, cycloidal reducers ensure smooth, stable motion. This precision is critical for applications such as CNC machining, where accuracy directly impacts product quality.

Working Principle

The Cycloidal Drive block represents a compact, high-ratio, speed-reduction mechanism that contains four key components:

● A cycloidal disc

● An eccentric cam

● Ring-gear housing

● Pin rollers

1.Drive the eccentric wheel to rotate through the input shaft, causing the cycloid wheel to produce eccentric motion;

2.The cycloidal teeth on the cycloidal gear mesh with the pin gear housing (pin gear ring), achieving speed reduction through the pin gear;

3. The output section transfers the motion of the cycloidal gear to the output shaft through rollers or pin shafts, achieving speed reduction and transmission.

Applications

• Industrial robot joints

• Automated conveyor line

• Machine tool rotary table

• Packaging machinery, printing machinery

• Steel and metallurgical equipment

Comparison

• Harmonic gear reducer: higher precision, smaller size, but inferior load-bearing capacity compared to cycloidal gear reducer.

• Planetary gear reducer: Compact structure, high transmission efficiency, but slightly inferior to cycloidal gear reducers in terms of accuracy and transmission ratio range.

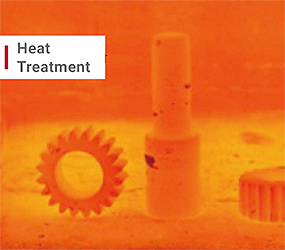

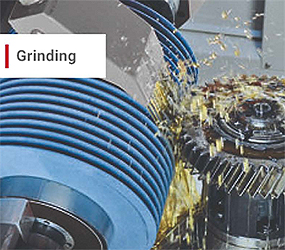

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package