High-Quality Planetary Spur Gear Drive Shaft for Gearbox Motor

Key advantages of gearbox motor systems

The planetary spur gear design evenly distributes torque across multiple gear teeth, reducing stress on individual components and enabling your gearbox motor to handle higher torque requirements (ranging from 50 N·m to 500 N·m, customizable to meet specific needs).

Compared to traditional spur gear shafts, the planetary configuration allows for a smaller footprint, making it an ideal choice for gearbox motors in tight spaces, such as automotive drivetrains, robotic arms, or compact industrial machinery.

High-quality materials and precision manufacturing reduce wear, meaning fewer replacements and less downtime for your gearbox motor. Our drive shafts also feature sealed bearings to prevent dust and debris buildup, further reducing maintenance requirements.

Our drive shafts are designed to fit most standard gearbox motor models, including 12V, 24V, and 380V industrial motors, and can be customized with different shaft lengths, gear counts, and mounting options to meet your exact specifications.

Ideal Applications Across Industries

1.Powering conveyors, mixers, and packaging equipment, where gearbox motors require consistent torque to perform heavy tasks.

2.Integrating with electric vehicle (EV) transmission motors or traditional internal combustion engine transmissions improves energy efficiency and ride smoothness.

3.Enabling precision motion in industrial robots, AGVs (automated guided vehicles), and collaborative robots, where gearbox motor accuracy is critical.

4.Ensuring quiet, reliable operation in diagnostic machines (such as MRI table motors) and surgical tools, where low noise and stability are uncompromising.

5.Boosting the performance of large appliances (such as washing machine transmission motors) and commercial HVAC systems.

Why choose our planetary spur gears?

We don't just sell components; we offer solutions tailored to your gearbox motor needs. Each gear undergoes rigorous quality control, from material testing (hardness, tensile strength) to performance testing (load capacity, noise level), to ensure compliance with ISO 9001 and DIN standards. Furthermore, our team of engineers offers free technical support: whether you need help selecting the right drive shaft size or a custom design for your gearbox motor, we're here to help.

Manufacturing Plant

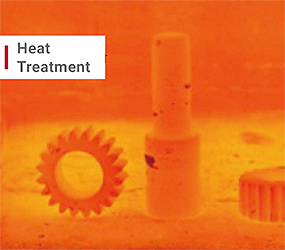

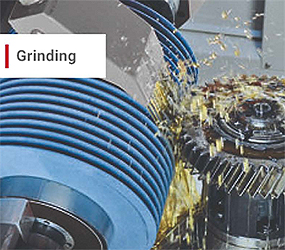

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package