What We Know About Helical Gears

Key Takeaways

Helical gears are one of the most widely used precision transmission components in mechanical engineering. Their teeth are cut at an angle to the axis of rotation, allowing gradual and continuous meshing between gear teeth. This design results in smoother operation, lower noise, and higher load capacity compared with spur gears.

Main Features

●Smooth and quiet transmission: The overlapping contact of helical teeth reduces vibration and noise, making them ideal for high‑speed applications.

●High load‑carrying capacity: Larger contact area improves strength and durability.

●Can transmit power between parallel shafts or crossed shafts.

Common Applications

●Automotive transmissions and differentials

●Electric vehicle reducers

●Industrial gearboxes

●Machinery tools

●Heavy‑duty mechanical equipment

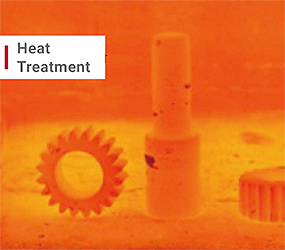

Materials & Heat Treatment

Common materials include alloy steels such as 20CrMnTi, 20CrMo, and 40Cr. Typical heat treatment processes include carburizing, quenching, and tempering to achieve high surface hardness and strong core toughness.

Advantages

●Stable running performance

●High precision and long service life

●Suitable for high‑speed and heavy‑load conditions

●Customizable in module, pressure angle, helix angle, and size

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

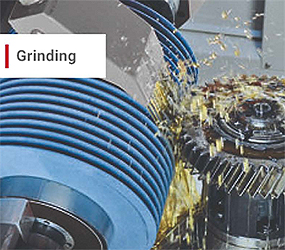

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package