Alloy steel spur gear shaft for high load hydraulic pump

Product Description

The commonly used material for spur gear shafts in hydraulic pumps is usually alloy steel.

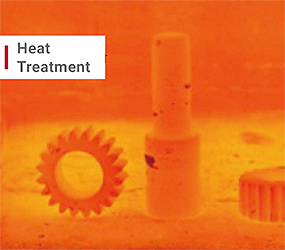

Alloy steel has excellent strength, toughness and wear resistance, making it suitable for handling the high loads and pressures encountered in hydraulic systems.Some specific grades of alloy steel commonly used include AISI 4140, AISI 4340 and AISI 8620. These materials can be heat treated to obtain the desired hardness and strength properties. In addition, surface treatments with materials such as nitriding or chromium or nickel plating can be used to enhance corrosion resistance and further increase the service life of the spur gear shaft.

Ultimately, the choice of specific materials may depend on the specific application and requirements of the hydraulic pump.

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

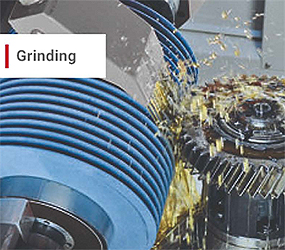

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

We will provide comprehensive quality documents for your approval before shipping.

1. Material report

2. Bubble drawing

3. Dimension report

4. Heat treatment report before heat treatment

5. Heat treatment report after heat treatment

6. Accuracy report

7. Pictures and All testing videos like Runout , Cylindricity etc

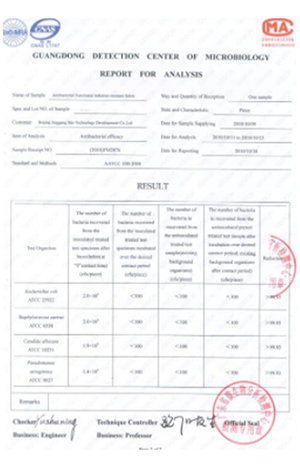

8. Other testing reports per customers’ requirement like flaw detection report

Drawing

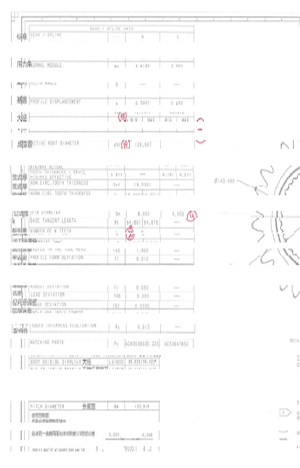

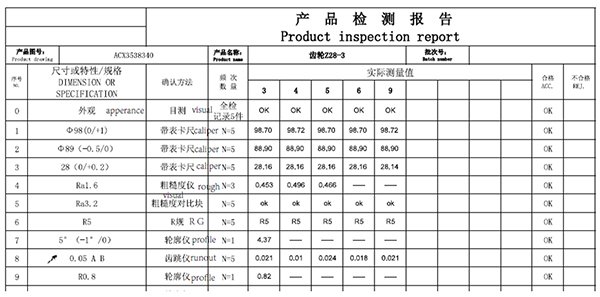

Dimension Report

Heat Treatment Report

Accuracy Report

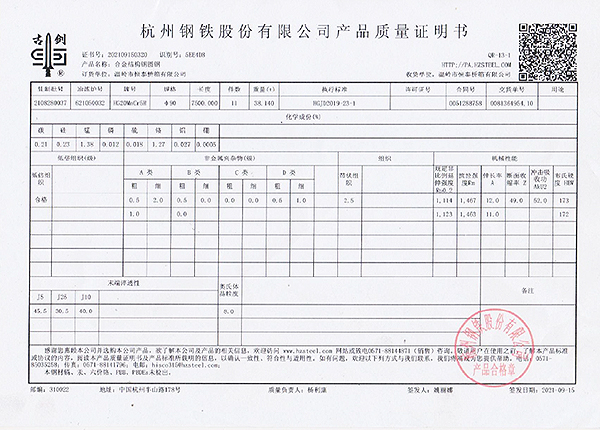

Material Report

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package