You’ll notice helical gears and straight gears work differently. Helical gears run smoother and quieter, perfect for high-speed machines. Straight gears give you better efficiency and cost less, making them great for racing or simple setups. Picking the right gear affects speed, noise, and how much load you handle.

Key Takeaways

●Helical gears work quietly and smoothly. They are good for fast machines like car transmissions.

●Straight gears cost less and work well. They are best for simple machines that do not need to be quiet or fast.

●You should pick the right gear for your project. Think about how much weight it will carry, how loud it is, and how much money you have.

Gear Types Overview

Helical Gears Explained

When you look at helical gears, you’ll notice their teeth are set at an angle, not straight across. This design helps them run smoother and quieter than other gears. You’ll find these gears in places where noise matters, like car transmissions or conveyor systems. They can handle bigger loads and work well at high speeds. Here are some common uses for helical gears:

●Automotive transmissions

●Printing presses

●Steel mills

●Food and textile machines

If you need a gear that keeps things quiet and can take on heavy work, helical gears are a smart choice.

Straight Gears Explained

Straight gears, also called spur gears, have teeth that point straight out from the center. These gears are simple and easy to make. You’ll see them in machines that don’t need to run super fast, like tractors or washing machines. Straight gears transfer power efficiently between parallel shafts. They’re great for jobs where you want to keep things simple and save money. Here’s a quick look at their features:

| Characteristic | Description |

|---|---|

| Straight Teeth | Teeth run parallel to the gear’s axis |

| Simple Design | Easy to manufacture and maintain |

| Efficiency | High power transmission efficiency |

| Noise | Can get loud at high speeds |

How They Work

Both gear types move power from one shaft to another, but they do it differently. Helical gears engage gradually because of their angled teeth. This means less shock and smoother movement. Straight gears, on the other hand, snap into place quickly, which can make them noisy and cause more wear. If you want quiet and smooth operation, go with helical gears. If you need something simple and efficient, straight gears might be your best bet.

Helical Gears vs. Straight Gears

Tooth Design and Alignment

The shape and direction of gear teeth are important. Helical gears have teeth that are cut at an angle. Straight gears have teeth that go straight across. This difference changes how each gear works and where you use them.

Here’s a simple table to show the differences:

| Feature | Helical Gears | Straight Gears |

|---|---|---|

| Tooth Angle | Cut at an angle (helix angle) to the axis | Parallel to the axis |

| Engagement | Smoother and more gradual engagement | Abrupt engagement |

| Manufacturing Complexity | More complex to manufacture and install | Easier to manufacture and install |

| Performance | Superior in high-speed and high-precision applications | Suitable for simplicity and cost-effectiveness |

| Alignment | Requires precise alignment during installation | Simpler alignment |

Helical gears need careful alignment when you put them in. Their angled teeth let them fit together slowly. This makes them quieter and smoother. Straight gears snap together fast. This can make them louder and cause more shaking.

Tip: If you want a quiet and smooth machine, pick gears with angled teeth.

Torque and Load Transfer

Let’s see how these gears move power. Helical gears can carry more load. Their angled teeth let many teeth touch at once. This spreads out the force and makes the gear stronger. You get smoother power and less chance of breaking a tooth.

Straight gears only have one tooth touching at a time. They can’t handle as much force. You might need bigger teeth to make them strong enough. If you need to move heavy things or want your gear to last, helical gears are better.

●Helical gears give you:

●

Higher strength

●Better load sharing

●Longer gear life

●Straight gears give you:

●

●Simpler design

●Good for lighter loads

Lateral Force vs. Direct Torque

Now let’s talk about how these gears push and pull. Helical gears make sideways (axial) forces. Their teeth slide against each other. You need strong bearings to keep things in place. If you don’t plan for these forces, your gear system can wear out or break.

●Helical gears:

●

Make axial loads that push along the shaft

●Need special bearings for these forces

●Can cause uneven load on the gear system

●Straight gears:

●

Only push straight across (no sideways force)

●Make it easy to build strong gearboxes

●Work well if you want less stress on bearings

Note: If you want a simple setup with less worry about extra forces, straight gears are a good choice. If you want quiet and smooth operation, remember to plan for the sideways push from helical gears.

Performance Comparison

Noise and Vibration

You’ll notice a big difference in sound when you compare these gears. Helical gears run much quieter because their angled teeth slide into place slowly. This smooth action cuts down on noise and vibration. If you’ve ever heard a loud whine from a machine, it probably used straight gears. These gears make a sharp, sudden contact, which gets noisy, especially at high speeds. In fact, helical gears can keep noise levels around 80-85 dBA, which is much easier on your ears.

●Straight gears: Make a loud whine, especially when spinning fast.

●Helical gears: Stay quiet and smooth, even at higher speeds.

Strength and Durability

You want your gears to last, right? Helical gears spread the load over several teeth at once. This means less stress on each tooth and a longer life for your gear. Both gear types can fail from things like fatigue, wear, or misalignment. However, helical gears handle heavy work better and resist breaking under pressure.

Tip: Always check your gear alignment. Misaligned gears wear out faster and can break.

Efficiency Differences

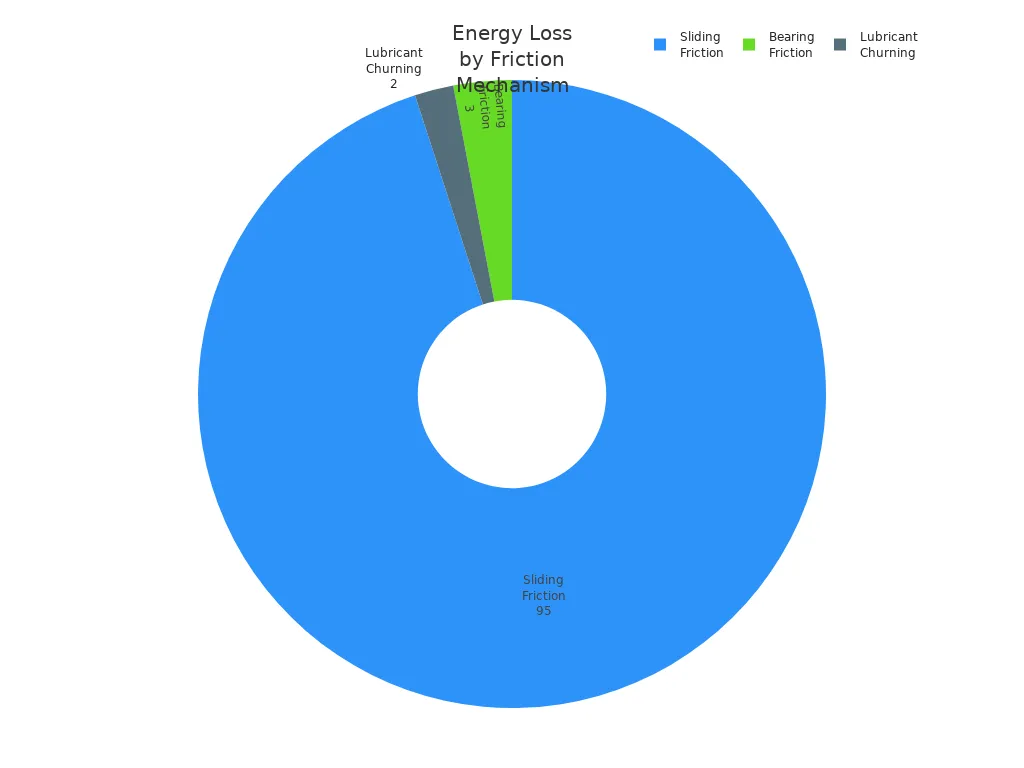

Straight gears win when it comes to efficiency. They don’t create sideways forces, so they waste less energy as heat. Helical gears, while strong and quiet, lose a bit more energy because their teeth slide and create friction. Good lubrication helps both types, but it’s extra important for helical gears to keep things cool and smooth.

Speed and Load Capacity

If you need to move heavy loads or run at high speeds, helical gears are your best bet. Their angled teeth let them handle more force and work well in tough jobs like car transmissions. Straight gears work best in simple, low-speed setups.

Here’s a quick table to help you compare:

| Feature | Helical Gears | Straight Gears |

|---|---|---|

| Noise & Vibration | Low | High |

| Strength & Durability | High | Moderate |

| Efficiency | Moderate | High |

| Speed Capacity | High (up to 6,000 rpm) | High (up to 6,000 rpm) |

| Load Capacity | High | Moderate |

Cost and Maintenance

Manufacturing and Purchase Cost

Price is important when you buy gears. Helical gears cost more than straight gears. Their angled teeth need special machines to make. This means more work and higher prices. Straight gears have a simple shape. They are cheaper to make and buy. If you want to save money, pick straight gears.

Here’s a quick list to compare:

●Helical gears: Cost more to make, cost more to buy, harder to install.

●Straight gears: Cost less, easy to find, simple to put in.

If you do not have much money or need many gears, straight gears help you spend less.

Maintenance Needs

All gears need care if you want them to last. Helical gears need more care because their design puts stress on bearings and seals. Oil leaks, bad alignment, and bearing problems happen more with helical gearboxes. Straight gears are easier to take care of, but you still need to check for damage and keep them clean.

Here’s a table with common problems and how to fix them for helical gears:

| Maintenance Issue | Description | Solutions |

|---|---|---|

| Leaks and Oil Contamination | Seals break and oil leaks or gets dirty | Check seals, use good materials |

| Misalignment | Uneven load makes gears wear out faster | Use tools to align, check often |

| Bearing Issues | Bearings get noisy or stop working | Add oil, use good bearings |

| Gear Tooth Chipping | Teeth break from heavy loads or not enough oil | Check often, add oil |

Tip: Check your gears often and keep them oiled. This helps your gears last longer. Do not forget to do maintenance, especially with helical gears.

Choosing the Right Gear

When to Use Helical Gears

You want smooth, quiet, and strong performance? Helical gears are your go-to. These gears shine in places where noise and vibration matter. Think about car transmissions, robots, or even wind turbines. They handle heavy loads and high speeds without breaking a sweat.

Here’s a quick table to help you decide if helical gears fit your project:

| Design Factor | What to Check | Why It Matters |

|---|---|---|

| Load and duty cycle | How much force and how often | Picks the right size and material |

| Speed and noise | How fast and how quiet you need | Makes sure gears stay smooth and quiet |

| Axial thrust | Can your bearings handle side push? | Stops early wear and shaft bending |

| Lubrication & heat | How will you keep gears cool? | Keeps things running and lasting |

| Accuracy | How precise must the gear be? | Affects noise and smooth movement |

| Cost and timeline | Your budget and delivery needs | Helps plan your project |

For example, car makers use helical gears in transmissions to keep rides quiet and smooth. Wind turbines rely on them for steady, silent power.

When to Use Straight Gears

Straight gears work best when you want simple, efficient, and budget-friendly solutions. You’ll see them in machines that don’t need to run quietly or at super high speeds, like farm equipment or basic gearboxes.

You trade some noise and vibration for lower cost and easy maintenance. Straight gears can be a smart pick for less critical jobs, especially if you keep them well-oiled and don’t push them too hard.

If you care more about saving money and getting the job done, straight gears make sense. Just remember, they get noisy when things speed up.

You now know helical gears run smoother and quieter, while straight gears keep things simple and efficient. Here’s a quick look:

| Gear Type | Advantages | Disadvantages |

|---|---|---|

| Helical | Quiet, strong, handles high speed | Needs special bearings |

| Straight | Simple, low cost | Noisy at high speeds |

Checklist for choosing:

●Need quiet and strength? Go helical.

●Want simple and cheap? Pick straight.

●Always match your gear to your project’s needs.

FAQ

What makes helical gears quieter than straight gears?

Helical gears have angled teeth. These teeth slide into contact slowly. You hear less noise and feel less vibration when you use them.

Can you mix helical and straight gears in one machine?

You should not mix them. They work differently. Mixing them can cause extra wear, noise, and even damage.

Which gear type lasts longer with heavy loads?

Helical gears usually last longer. Their angled teeth share the load across more teeth. This reduces stress and helps prevent gear failure.

Post time: Feb-05-2026