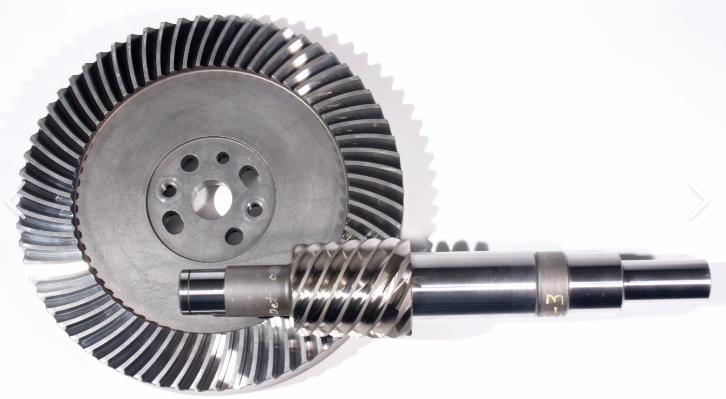

A hypoid gear is a specialized type of gear designed for transmitting motion and power between non-intersecting, non-parallel shafts. It is a variation of the spiral bevel gear, distinguished by its axis offset and unique tooth geometry.

Definition

A hypoid gear is a type of spiral bevel gear in which the axes of the driving and driven gears do not intersect and are instead offset from each other. This configuration enables smoother and more efficient transmission of power between shafts positioned at an angle.

Structural Features

● Tooth Geometry:

● The tooth surface of a hypoid gear is part of a hyperbolic paraboloid, giving it a complex, curved profile. While similar to spiral bevel gears, hypoid gears exhibit a distinctive hyperbolic tooth shape that allows for more gradual meshing.

● Axis Offset:

● Unlike bevel gears, hypoid gears feature an offset between the input and output shafts, which enables compact design layouts, especially in automotive drivetrains.

Working Principle

● Meshing Mechanism:

● Hypoid gears engage through line contact along the tooth surfaces, providing a more even distribution of contact stress compared to point-contact gears. This contact allows for the smooth transfer of torque and rotational motion.

● Motion Characteristics:

● Due to the axial offset, the gears exhibit a combination of rotational and sliding motion, which enhances load-carrying capacity and efficiency.

Performance Advantages

✅ High Load Capacity:

Uniform distribution of contact stress across the tooth surface allows hypoid gears to handle heavy loads effectively.

✅ High Transmission Efficiency:

The line-contact meshing reduces sliding friction, resulting in a typical efficiency of 95% or higher.

✅ Smooth and Quiet Operation:

The tooth shape and contact mechanics produce low noise and vibration, ensuring stable performance.

Application Areas

● Automotive Industry:

Extensively used in rear axle drive systems, especially in rear-wheel-drive vehicles.

● Aerospace:

Found in critical components like engine drive systems and landing gear mechanisms.

● Industrial Machinery:

Used in high-load applications such as cranes, excavators, and mining equipment.

● Robotics & Automation:

Ideal for robotic arms and precision automation systems requiring compact design and high torque.

● Marine Propulsion:

Applied in marine gear systems to transfer power from engines to propeller shafts.

Summary

Hypoid gears offer a powerful solution for complex power transmission needs, especially where space is limited and high torque is required. Their high efficiency, quiet operation, and heavy load capabilities make them indispensable in sectors ranging from automotive to aerospace and industrial automation.

Post time: Jun-04-2025