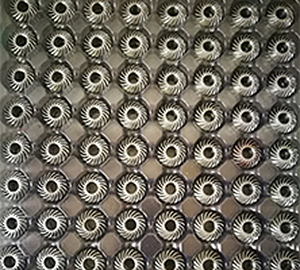

Supplier Custom Hypoid Bevel Gears Used in Robotic Arms

Machining Method of Hypoid Gears

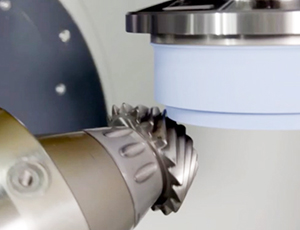

Hypoid gears can be machined using two different methods: grinding and lapping. Domestic equipment can process hypoid gears, but high-precision, high-end processing is usually done by foreign equipment, such as Gleason and Oerlikon.

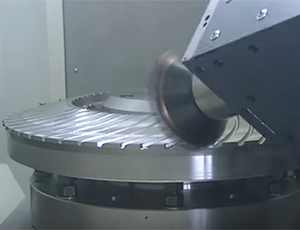

In the gear grinding process, face milling is recommended for the gear cutting process. On the other hand, it is recommended to use face hobbing during grinding. Gears machined with face milling have bevel teeth, while gears machined with face hobbing have contour teeth.

A typical machining process includes rough machining after preheating and finishing after heat treatment. For face hobbing, the gears must be ground and fitted after heating. Although the gears using the grinding technology do not need to be matched in theory, the matching method is still generally used in actual operation to solve the problems of assembly errors and system deformation.

Manufacturing Plant

The first hypoid gear factory in China introduced UMAC technology from the United States, creating history and revolutionizing the processing technology of hypoid gears, improving speed, efficiency and cost-effectiveness. This has led to exponential growth in domestic and international demand for China's hypoid gear industry, establishing China's position as a manufacturing and export hub for hypoid gears, while consolidating its leadership in advanced manufacturing technologies.

Flow of Production

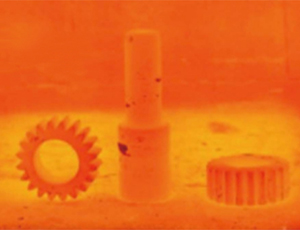

Raw Material

Rough Cutting

Turning

Quenching and Tempering

Gear Milling

Heat Treatment

Gear Grinding

Testing

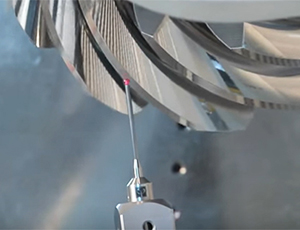

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

We will provide comprehensive quality documents for your approval before shipping.

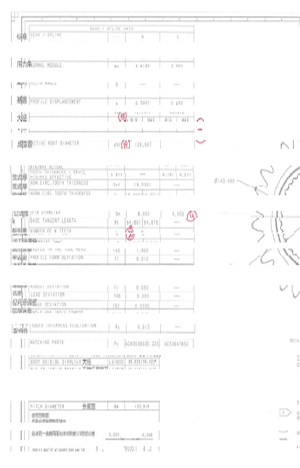

Drawing

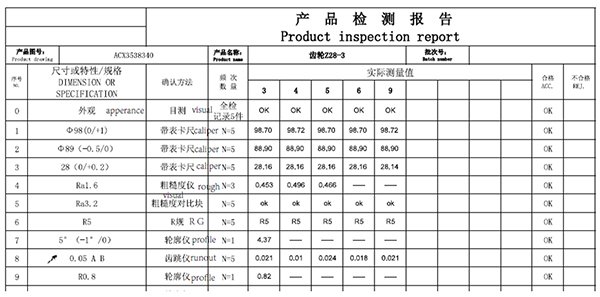

Dimension Report

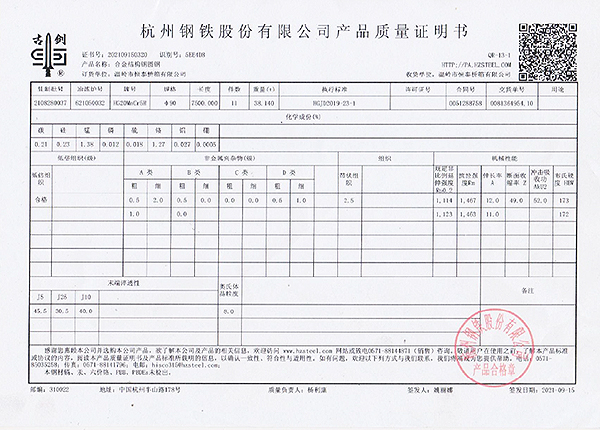

Heat Treatment Report

Accuracy Report

Material Report

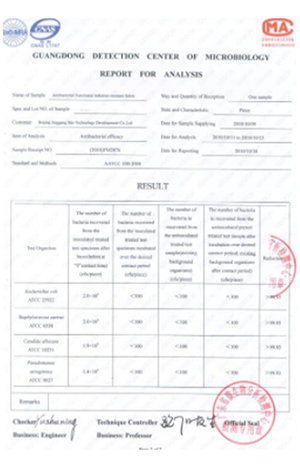

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package