Planetary Gearbox: The Ultimate Solution for High-Performance Transmission

Key Advantages of Planetary Gearboxes

1.Compact Design & High Power Density:The planetary arrangement allows multiple planet gears to share the load, reducing the overall size while maintaining high torque output. For instance, a planetary gearbox can achieve the same torque as a conventional parallel-shaft gearbox but in 30–50% less space.

2.Superior Load-Bearing Capacity:With multiple planet gears distributing the load, planetary gearboxes excel in shock resistance and heavy-duty applications. They are commonly used in excavators and wind turbines, where sudden loads or vibrations are prevalent.

3.High Efficiency & Low Energy Loss:Efficiency typically ranges from 95–98%, far exceeding worm gearboxes (70–85%). This efficiency minimizes heat generation and energy waste, making it ideal for electric vehicles and industrial machinery.

4.Wide Range of Reduction Ratios:Single-stage planetary gearboxes can achieve ratios up to 10:1, while multi-stage systems (e.g., 2 or 3 stages) can reach ratios exceeding 1000:1. This flexibility allows customization for precision robotics or high-torque industrial drives.

5.Precision & Backlash Control:Standard industrial models have backlash (play between gears) of 10–30 arcmin, while precision-grade versions (for robotics or servo systems) can achieve 3–5 arcmin. This precision is critical for applications like CNC machining or robotic arms.

How It Works

The planetary gear system operates on the principle of epicyclic gearing, where:

1.The sun gear is the central driving gear.

2.Planet gears are mounted on a carrier, rotating around the sun gear while also spinning on their own axes.

3.The ring gear (annulus) encloses the planet gears, either driving or being driven by the system.

By fixing or rotating different components (sun, ring, or carrier), various speed and torque ratios can be achieved. For example, fixing the ring gear increases torque, while fixing the carrier creates a direct drive.

Applications Across Industries

| Industry | Use Cases | Why Planetary Gearboxes Excel Here |

|---|---|---|

| Industrial Automation | CNC machines, conveyor systems, packaging equipment | Compact design fits tight spaces; high efficiency reduces energy costs. |

| Robotics | Joint drives in robotic arms, autonomous vehicles (AGVs) | Low backlash and precise control enable smooth, accurate movements. |

| Automotive | Electric vehicle drivetrains, automatic transmissions (AT), hybrid systems | High power density suits space-constrained EV designs; efficiency boosts range. |

| Aerospace | Aircraft landing gear, satellite antenna positioning, drone propulsion | Lightweight design and reliability meet strict aerospace standards. |

| Renewable Energy | Wind turbine gearboxes, solar tracker systems | High torque capacity handles heavy loads in wind turbines; precision ensures solar panel alignment. |

| Construction | Excavators, cranes, bulldozers | Shock resistance and durability withstand harsh operating conditions. |

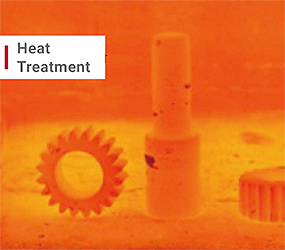

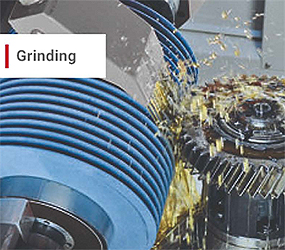

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package