Custom Planetary Gear set for Medical Equipment

Product Description

Planetary gears, also known as epicyclic gears, are used in many applications that require high gear ratios, compact size, and precise speed control.

Some common uses of planetary gears include:

- Automobile transmission: Planetary gears are widely used in automatic transmissions, which can provide a variety of forward and reverse gear ratios.

- Robotics and automation: Planetary gears can help robots and other automated machines move more precisely. They also help reduce drivetrain size while still maintaining high torque output.

- Wind Turbines: Planetary gears are used in the transmission system of wind turbines to help increase the rotational speed of the blades, thereby increasing the power generation.

- Aerospace industry: Planetary gears are used in many aircraft applications, including helicopter transmissions, engine accessory drives, and actuator systems.

- Machine tools: Planetary gears are used in precision machine tools that require high precision and precise speed control. 6. Construction machinery: Planetary gears are used in various types of construction equipment, such as cranes, to provide high torque and multiple transmission ratios.

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

We will provide comprehensive quality documents for your approval before shipping.

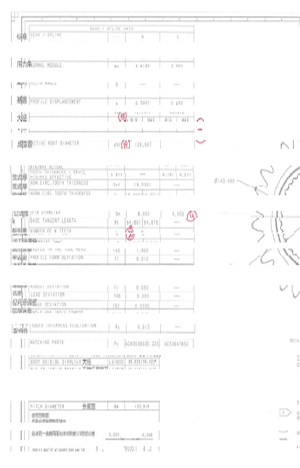

Drawing

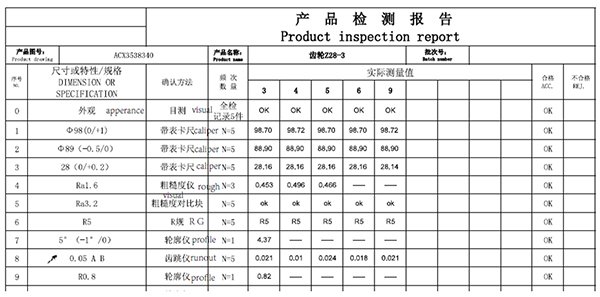

Dimension Report

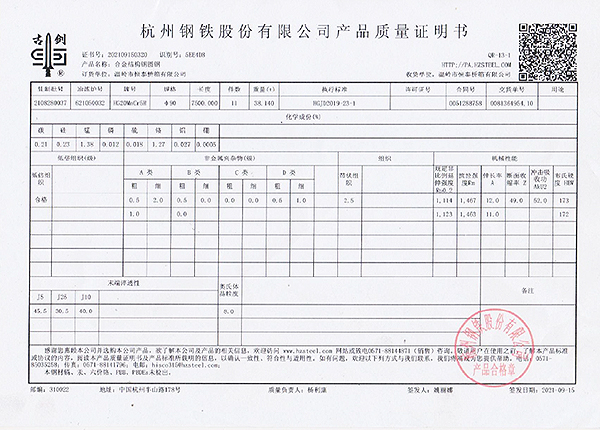

Heat Treatment Report

Accuracy Report

Material Report

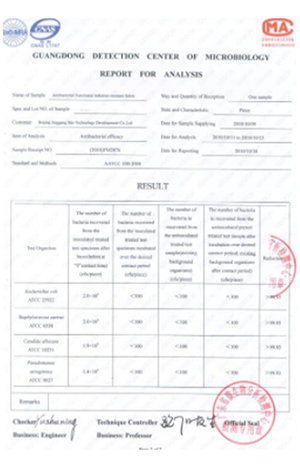

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package