Supplier High Precision Ring and Pinion Gear Set

Bevel Gear Applications

Bevel gears have a wide range of applications in various industries due to their ability to transmit motion between intersecting axes at different angles. Some common applications for bevel gears include:

1. Automobile industry: Bevel gears are used in the differential mechanism of vehicles to transmit power from the drive shaft to the wheels. They allow the wheels to rotate at different speeds while maintaining power delivery from the engine.

2. Shipbuilding industry: Bevel gears are used in ship propulsion systems to transmit power from the engine to the propeller shaft, thereby achieving efficient power transmission in a small space.

3. Aerospace industry: Bevel gears are used in aircraft landing gear systems to help transmit power between the motor and the landing gear mechanism, allowing for smooth and controlled deployment and retraction.

4. Industrial machinery: Bevel gears are commonly found in industrial machinery such as printing machines, milling machines, and packaging equipment, and are used to transmit power between intersecting shafts at different angles.

Flow of Production

Raw Material

Rough Cutting

Turning

Quenching and Tempering

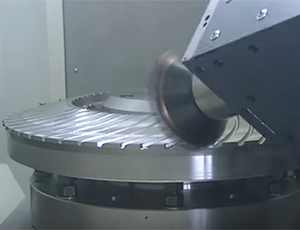

Gear Milling

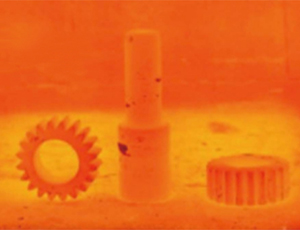

Heat Treatment

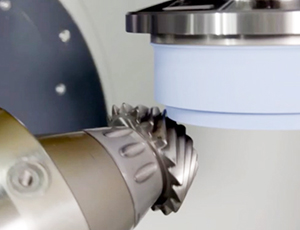

Gear Grinding

Testing

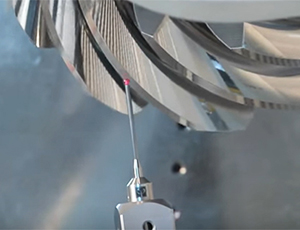

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

We will provide comprehensive quality documents for your approval before shipping.

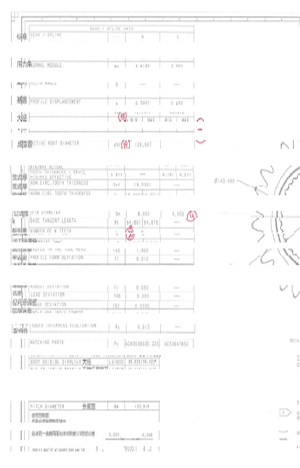

Drawing

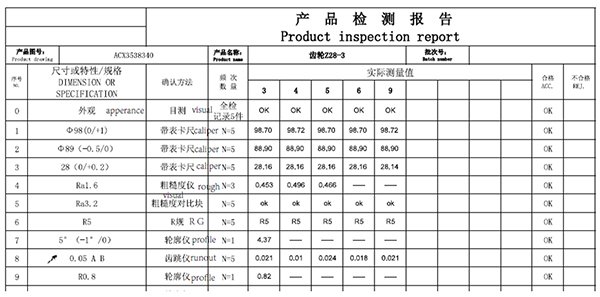

Dimension Report

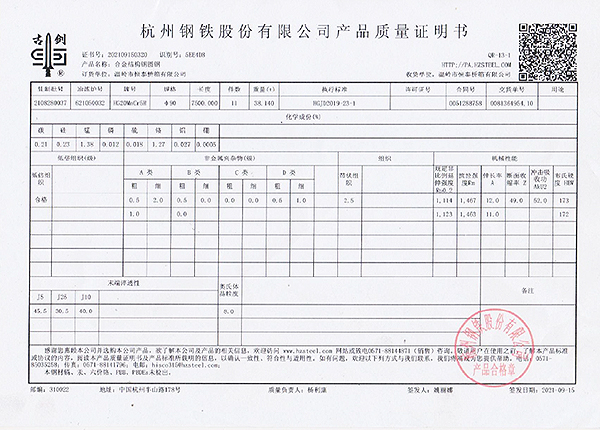

Heat Treatment Report

Accuracy Report

Material Report

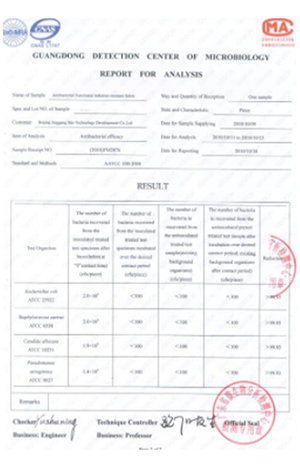

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package