DIN6 inner ring spur gear for Planetary Reducers

Product Description

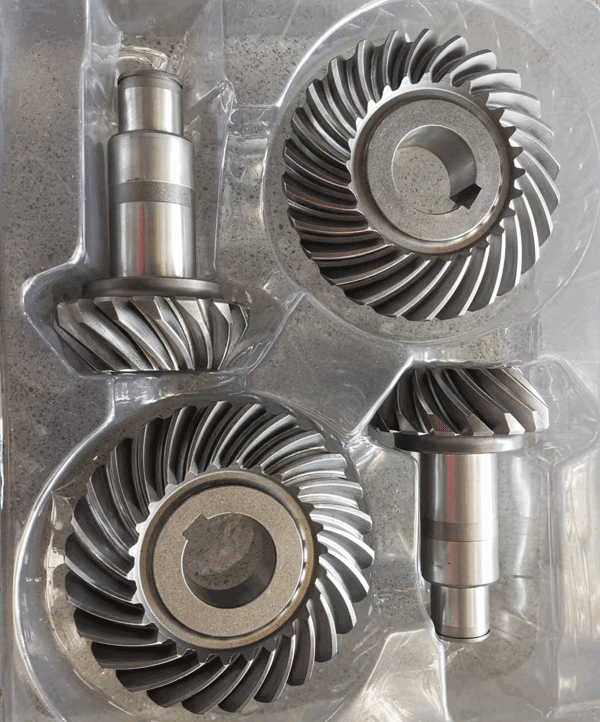

Ring gears are usually made of steel that is heated and forged or cast into the desired shape. After the initial forming process, the ring gear is machined to obtain the exact tooth shape and diameter required for the gear system. This process usually involves CNC machining or gear hobbing. Finally, the gears are heat treated to increase their strength and durability. Some key features of ring gears include their ability to transmit large amounts of torque, even load distribution, and compact design. They also offer high gear reduction ratios, which are useful in applications requiring low speed and high torque output. Ring gears are used in a wide range of industrial machinery. They are commonly used in heavy equipment such as cranes, excavators, and mining equipment, as well as in wind turbines, automotive transmissions, and other high-torque system applications.

Manufacturing Plant

Our company has a production area of 200,000 square meters, equipped with the most advanced production and inspection equipment to meet customers' requirements. In addition, we have recently introduced a Gleason FT16000 five-axis machining center, the largest machine of its kind in China, specially designed for gear manufacturing according to the cooperation between Gleason and Holler.

- Any modules

- Any number of teeth required

- Highest accuracy grade DIN5

- High efficiency,high Precision

We pride ourselves on being able to offer exceptional productivity, flexibility and cost-effectiveness to our customers with low-volume needs. You can rely on us to consistently deliver high-quality products to your exact specifications.

Flow of Production

Raw Material

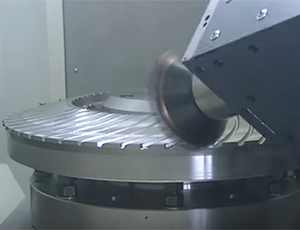

Rough Cutting

Turning

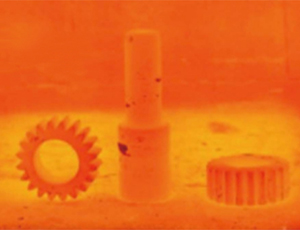

Quenching and Tempering

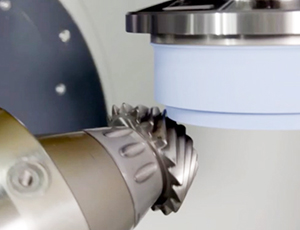

Gear Milling

Heat Treatment

Gear Grinding

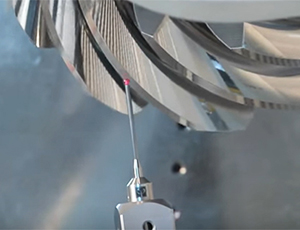

Testing

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, German Marl cylindricity testers and Japanese roughness testers, etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

We will provide comprehensive quality documents for your approval before shipping.

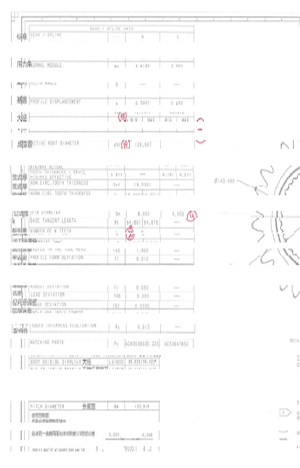

Drawing

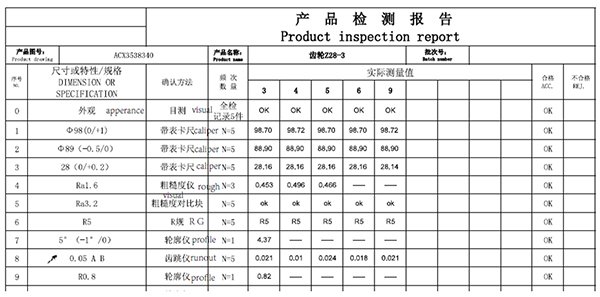

Dimension Report

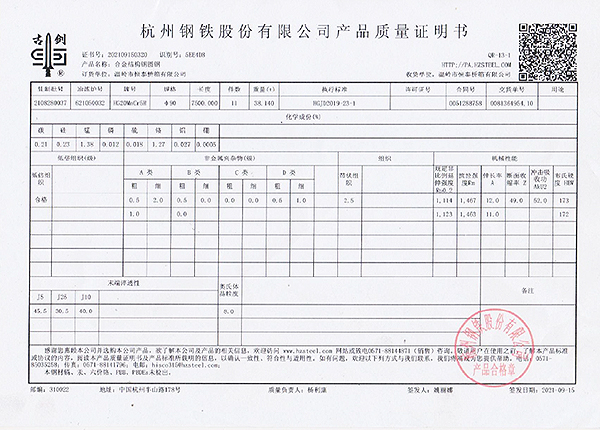

Heat Treatment Report

Accuracy Report

Material Report

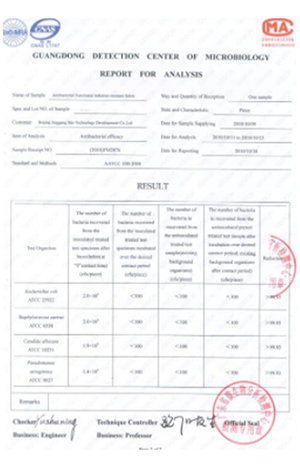

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package