Helical Rack And Pinion Gear For Automated Robotic Arms

Application Industry

The rack and pinion has a wide range of applications.

Automotive

- Power Steering Rack and Pinion Assembly

- Steering Gear Rack and Pinion Unit

- Steering Rack and Pinion Kit

- Rack and Pinion Steering Gear Box

Industrial Machinery

- Linear Motion Rack and Pinion System

- Rotary Motion Rack and Pinion Drive

- Actuator Rack and Pinion Assembly

- Positioning System with Rack and Pinion

Material Handling

- Crane Hoist Rack and Pinion System

- Scissor Lift Rack and Pinion Drive

- Cargo Elevator Rack and Pinion Assembly

- Automated Storage and Retrieval System (ASRS)

Robotics

- Robotic Arm Rack and Pinion Drive

- Linear Actuator with Rack and Pinion System

- CNC Machine Tool Rack and Pinion Drive

- Gantry Robot Rack and Pinion Assembly

Construction

- Scaffolding Rack and Pinion System

- Elevator Rack and Pinion Drive

- Bridge Formwork Rack and Pinion Assembly

- Mast Climbing Work Platform Rack and Pinion Drive

Medical Equipment

- Medical Table Positioning Rack and Pinion System

- Imaging Equipment Rack and Pinion Drive

- Robotic Surgery Rack and Pinion Assembly

- Prosthetic Limb Rack and Pinion Drive

Manufacturing Plant

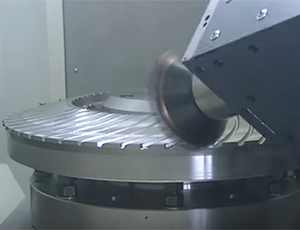

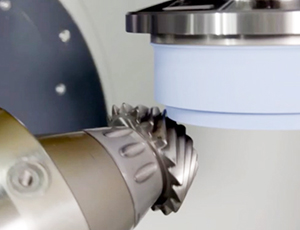

Our company has a production area of 200,000 square meters, equipped with the most advanced production and inspection equipment to meet customers' requirements. In addition, we have recently introduced a Gleason FT16000 five-axis machining center, the largest machine of its kind in China, specially designed for gear manufacturing according to the cooperation between Gleason and Holler.

- Modulus range: 0.5-42M

- Accuracy class: 5-10.

- Grade 5, up to 1000 mm in length in one piece

- Grade 6, in length up to 2000 mm in one piece.

We pride ourselves on being able to offer exceptional productivity, flexibility and cost-effectiveness to our customers with low-volume needs. You can rely on us to consistently deliver high-quality products to your exact specifications.

Flow of Production

Raw Material

Rough Cutting

Turning

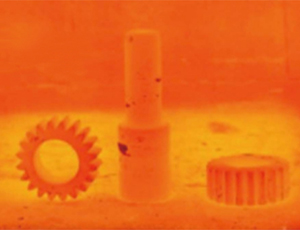

Quenching and Tempering

Gear Milling

Heat Treatment

Gear Grinding

Testing

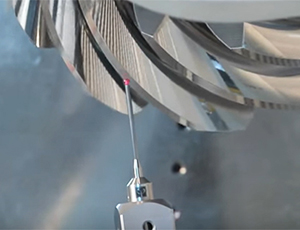

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages